Adhesive vinyl CHECK expert 2514E Breda oak long and wide plank premium

€29.99* /

Ready to ship today, Delivery time appr. 3-6 workdays (MO-FR)

| Format: | Lang- und Breitdiele |

|---|---|

| Installation Method: | verklebt |

| Joint Pattern:: | 4-seitige Fase |

| Length: | 1520 |

| Plank Design: | 1-Stab Landhausdiele |

| Product Type: | Vinyl |

| Residential Warranty: | 15 Jahre private Garantie |

| Surface Texture: | Strukturprägung |

| Thickness: | 2, 2,5 |

| Width: | 238 |

| Wood Type: | Eiche |

| Farbton: | hell |

| Nutzschicht Vinyl: | 0,55 mm |

| Garantie gew.: | 15 Jahre gewerbliche Garantie |

The professional floor

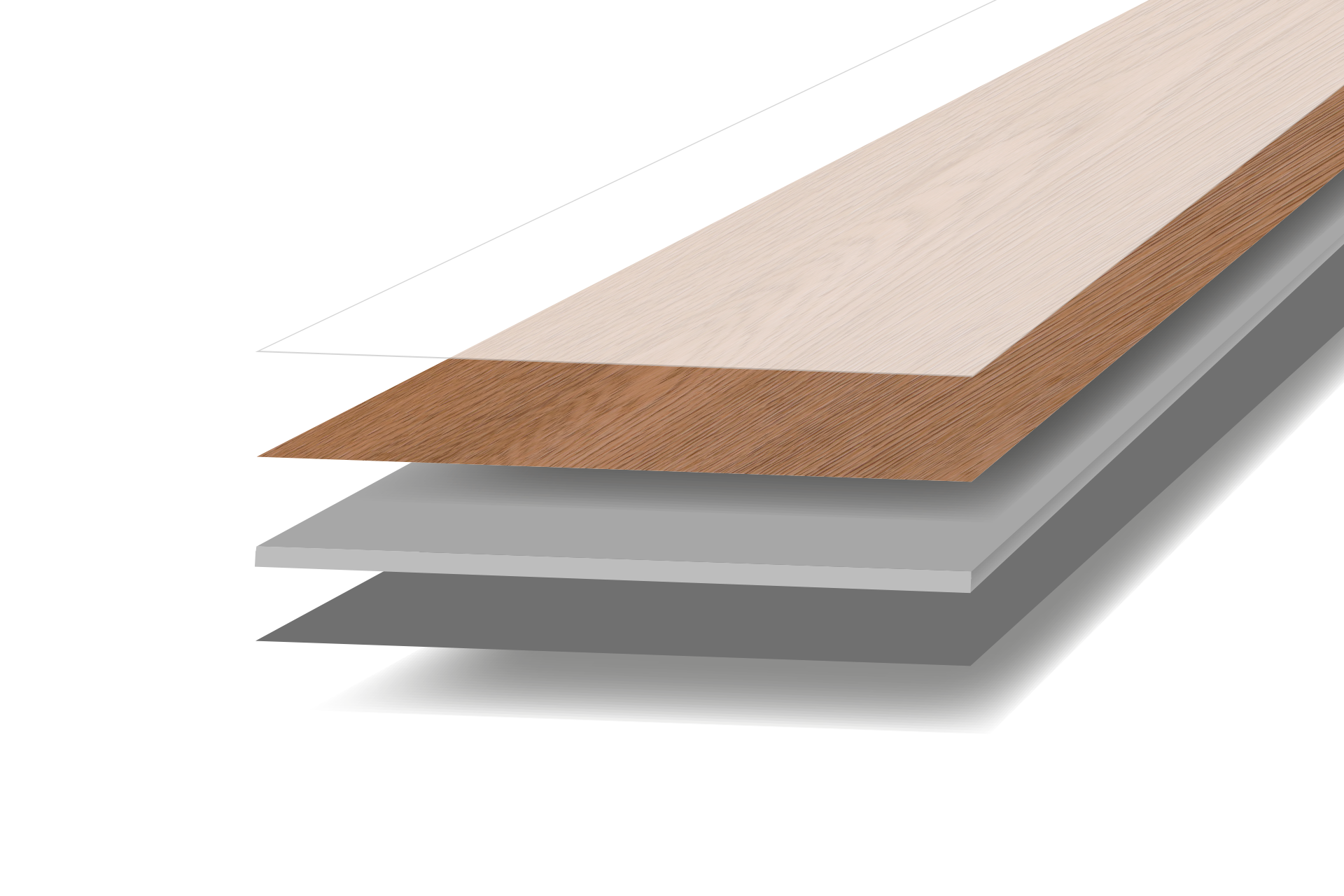

Vinyl floors that are laid using adhesive are known as adhesive vinyl floors or dryback floors. These floors consist of several layers of vinyl that are bonded together to form a plank during production. As adhesive vinyl is glued directly to the subfloor, it does not slip even under very heavy loads. Accordingly, adhesive vinyl flooring is particularly suitable for commercial areas that are highly frequented and subject to above-average wear. As they have an overall service class of up to 42, they can be found in the industrial sector, in shop fitting and at trade fairs and events.

To ensure that adhesive vinyl floors ultimately deliver what they promise, they must be glued down correctly. This first requires thorough preparation of the floor itself. In addition to dirt, any unevenness must also be removed. If the subfloor is particularly uneven, it is advisable to sand it down, as the unevenness could otherwise show in the adhesive vinyl. Next, the adhesive is applied to the subfloor, whereby it is particularly important to spread it neatly and evenly. The vinyl floor is now carefully laid. Once this has been done, a certain drying time must be observed during which the floor must not be walked on. This usually depends on various factors. These include the room temperature, the humidity and the type of adhesive used.

The all-round carefree floor

Whether in industry, in busy commercial areas or at home - dryback vinyl floors that are glued down are versatile. They are very robust and extremely hard-wearing, which is why they are particularly popular in high-traffic areas. With a maximum thickness of 2.5 mm, adhesive vinyl floors are ideal for refurbishments and renovations.